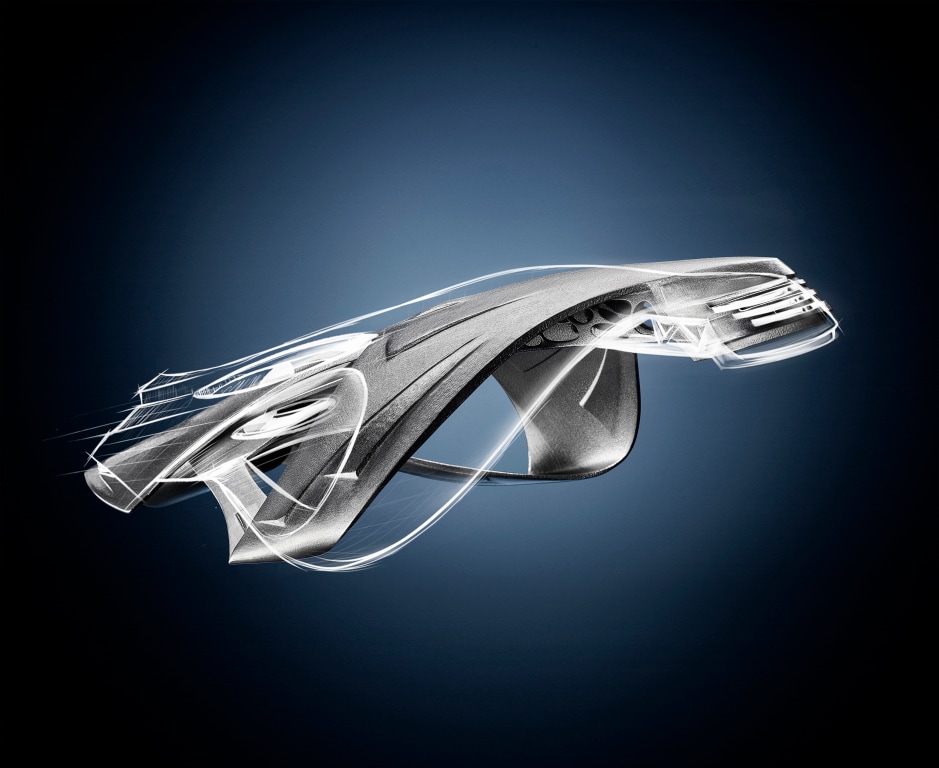

Revolution in manufacturing industry

Additive manufacturing has revolutionised the way things are made. It has opened up new and exciting possibilities for designers, customers and industry alike. At a low cost and in a short timeframe, even complex geometries can be built. It allows extensive customisation, manufacturing flexibility, and on-demand delivery, and has in some fields long advanced from mere prototyping to mass production.

As in all manufacturing processes, the quality of the end product greatly depends on the properties of the base material and the precision of the machinery. Process gases therefore play a vital role in additive manufacturing and are involved in every step of the AM fabrication chain – from metal powder production to surface finishing. Thanks to Linde’s gas and metallurgy expertise, we have been the partner of choice since the earliest developments of the additive manufacturing industry when it comes to finding the right supplier of world-class industrial and specialty gases as well as gas supply solutions.